NEWS

Contact us

:1 Floor, No. 8 Huashan Road, Shanyang Town, Jinshan District, Shanghai

:+86 021-31170068

: www.ys-stamp.com

:sales@ys-stamp.com

:+86 021-31170068

: www.ys-stamp.com

:sales@ys-stamp.com

Your locations is:News

2021/4/30What details should be paid attention to during the use of oil refining safety valvesThe safety valve has great value and significance for safe operation and ensuring safe operation. In order to play the actual value and function of the safety valve, it is very important to pay attention to details in the process of use. As the saying goes, the details determine the success or failure, and the details of the use of the safety valve determine the specific value of the safety valve. Refining safety valves are widely used in the oil refining industry, and have a huge role in regulating pipeline pressure and protecting oil refining safety. So what details should be paid attention to during the use of oil refining safety valves? 1. The correct installation is the same for any mechanical equipment. If it is not installed correctly, the value will be lost and the service

2021/4/30What details should be paid attention to during the use of oil refining safety valvesThe safety valve has great value and significance for safe operation and ensuring safe operation. In order to play the actual value and function of the safety valve, it is very important to pay attention to details in the process of use. As the saying goes, the details determine the success or failure, and the details of the use of the safety valve determine the specific value of the safety valve. Refining safety valves are widely used in the oil refining industry, and have a huge role in regulating pipeline pressure and protecting oil refining safety. So what details should be paid attention to during the use of oil refining safety valves? 1. The correct installation is the same for any mechanical equipment. If it is not installed correctly, the value will be lost and the service

View more 2021/4/23Olympus unveiled at 2021 China World Expo to fully demonstrate environmental protection hard-core technologyRecently, the 22nd China Environment Expo 2021 (hereinafter referred to as "China Environment Expo") was held at the Shanghai New International Expo Center. The China Environment Expo started in 2000. With more than 20 years of industry experience in the Chinese market and the global resources of the parent exhibition IFAT in Munich, it has grown into an important professional exhibition and exchange platform for the global ecological environment governance industry. Olympus attended this industry event as an exhibitor. During the exhibition, Olympus exhibited "Vanta Handheld XRF Analyzer" and "Terra II Portable XRD Analyzer", sharing advanced experience in soil detection analysis and solid waste recycling with many companies, fully demonstrating Olympus High-quality competitivene

2021/4/23Olympus unveiled at 2021 China World Expo to fully demonstrate environmental protection hard-core technologyRecently, the 22nd China Environment Expo 2021 (hereinafter referred to as "China Environment Expo") was held at the Shanghai New International Expo Center. The China Environment Expo started in 2000. With more than 20 years of industry experience in the Chinese market and the global resources of the parent exhibition IFAT in Munich, it has grown into an important professional exhibition and exchange platform for the global ecological environment governance industry. Olympus attended this industry event as an exhibitor. During the exhibition, Olympus exhibited "Vanta Handheld XRF Analyzer" and "Terra II Portable XRD Analyzer", sharing advanced experience in soil detection analysis and solid waste recycling with many companies, fully demonstrating Olympus High-quality competitivene

View more 2021/4/16Master valve core technology, innovation and developmentIn recent years, throughout the valve industry, many valve research and development areas still have many deficiencies and shortcomings, and master the core technology of the valve to promote the high-quality development of China's economy, improve the comprehensive strength of the country has a very important significance. How to improve the core technology innovation ability of China's industrial products and firmly grasp the initiative of science and technology development in their own hands is a subject and challenge faced by every plus enterprise and every technology research and development personnel. To be sure, some companies have achieved success on the road to innovation and research. It has its own set of complete system on technology. The first is to increase the alloc

2021/4/16Master valve core technology, innovation and developmentIn recent years, throughout the valve industry, many valve research and development areas still have many deficiencies and shortcomings, and master the core technology of the valve to promote the high-quality development of China's economy, improve the comprehensive strength of the country has a very important significance. How to improve the core technology innovation ability of China's industrial products and firmly grasp the initiative of science and technology development in their own hands is a subject and challenge faced by every plus enterprise and every technology research and development personnel. To be sure, some companies have achieved success on the road to innovation and research. It has its own set of complete system on technology. The first is to increase the alloc

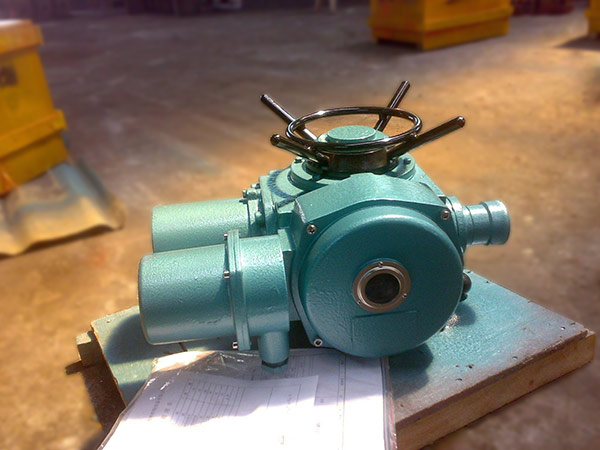

View more 2021/4/9What are the common faults of valve motorLow protection level: the valve motor for Denso is fully enclosed squirrel cage structure, short-time intermittent working system (10min) self-cooling type.According to the requirements of GB4942.1-85, the lowest protection grade is IP44, the highest protection grade is IP68.Valve operating conditions and different environments, the requirements of the protection level is also different.The low level of protection will cause the internal cavity of the motor to be damp or dust and other foreign matter invasion, and the insulation resistance value of the motor will decline and cause damage.Improper packaging, transportation and storage: the package of electric valve should be rainproof, moisture-proof and dust-proof, and the package should be firm and reliable.Rainproof measures shoul

2021/4/9What are the common faults of valve motorLow protection level: the valve motor for Denso is fully enclosed squirrel cage structure, short-time intermittent working system (10min) self-cooling type.According to the requirements of GB4942.1-85, the lowest protection grade is IP44, the highest protection grade is IP68.Valve operating conditions and different environments, the requirements of the protection level is also different.The low level of protection will cause the internal cavity of the motor to be damp or dust and other foreign matter invasion, and the insulation resistance value of the motor will decline and cause damage.Improper packaging, transportation and storage: the package of electric valve should be rainproof, moisture-proof and dust-proof, and the package should be firm and reliable.Rainproof measures shoul

View more 2021/4/2Sustainable development of renewable energyRenewable energy is a natural green energy that does not emit pollutants or greenhouse gases. Its rapid development has laid a solid foundation for the construction of ecological civilization.The 14th Five-Year Plan is a critical and critical period for the transformation to low-carbon energy. We will push forward the steady realization of the carbon peak and carbon neutral targets, and the "staying power" of the development of renewable energy should not be slurred. Fast-growing renewable energy is becoming a major force in China's drive to reach a carbon peak and be carbon neutral.At a recent press conference held by the State Council Information Office, a person in charge of the National Energy Administration said that China's renewable energy development and utilization scale

2021/4/2Sustainable development of renewable energyRenewable energy is a natural green energy that does not emit pollutants or greenhouse gases. Its rapid development has laid a solid foundation for the construction of ecological civilization.The 14th Five-Year Plan is a critical and critical period for the transformation to low-carbon energy. We will push forward the steady realization of the carbon peak and carbon neutral targets, and the "staying power" of the development of renewable energy should not be slurred. Fast-growing renewable energy is becoming a major force in China's drive to reach a carbon peak and be carbon neutral.At a recent press conference held by the State Council Information Office, a person in charge of the National Energy Administration said that China's renewable energy development and utilization scale

View more 2021/3/26Control valve common failure analysis and solutionsThe control valve is widely used in oil refining and chemical industry. It is used to control the flow rate, pressure and liquid level of the fluid in the production process.In the application of control valves, calculation and selection is the premise, installation and debugging is the key, use and maintenance is the purpose.If the selection of the control valve is not appropriate, improper installation or debugging is not good, it will not play a regulating role.Therefore, it is very important to be familiar with the control valve working principle and maintenance skills. Principle of control valve Pneumatic control valve to compressed air as power source, through the cylinder, film as the actuator, and with the help of electrical valve positioner, converter, solenoid val

2021/3/26Control valve common failure analysis and solutionsThe control valve is widely used in oil refining and chemical industry. It is used to control the flow rate, pressure and liquid level of the fluid in the production process.In the application of control valves, calculation and selection is the premise, installation and debugging is the key, use and maintenance is the purpose.If the selection of the control valve is not appropriate, improper installation or debugging is not good, it will not play a regulating role.Therefore, it is very important to be familiar with the control valve working principle and maintenance skills. Principle of control valve Pneumatic control valve to compressed air as power source, through the cylinder, film as the actuator, and with the help of electrical valve positioner, converter, solenoid val

View more 2021/3/19How to select valve material under high temperature condition?Working condition of high temperature including high temperature, high temperature Ⅰ Ⅱ, high temperature, high temperature Ⅲ Ⅳ, high temperature, high temperature Ⅴ level, the following were introduced. 1, Sub-high temperature Sub-high temperature refers to the valve operating temperature in the 325 ~ 425℃ region.If the medium is water and steam, mainly use WCB, WCC, A105, WC6 and WC9.If the medium is sulfur-containing oil, mainly with anti-sulfide corrosion of C5, CF8, CF3, CF8M and CF3M, etc.They are commonly used in oil refinery atmospheric and vacuum units and delayed coking units. At this time, the valves made of CF8, CF8M, CF3 and CF3M are not used for corrosion of acid resistant solutions, but for sulfur- containing oil and gas pipelines.In this working c

2021/3/19How to select valve material under high temperature condition?Working condition of high temperature including high temperature, high temperature Ⅰ Ⅱ, high temperature, high temperature Ⅲ Ⅳ, high temperature, high temperature Ⅴ level, the following were introduced. 1, Sub-high temperature Sub-high temperature refers to the valve operating temperature in the 325 ~ 425℃ region.If the medium is water and steam, mainly use WCB, WCC, A105, WC6 and WC9.If the medium is sulfur-containing oil, mainly with anti-sulfide corrosion of C5, CF8, CF3, CF8M and CF3M, etc.They are commonly used in oil refinery atmospheric and vacuum units and delayed coking units. At this time, the valves made of CF8, CF8M, CF3 and CF3M are not used for corrosion of acid resistant solutions, but for sulfur- containing oil and gas pipelines.In this working c

View more 2021/3/12The construction and operation of rural sewage treatment facilities in China can still reach one trillion levelsThe consensus in the industry is that the market environment has indeed changed profoundly.The industry generally believes that due to the increasingly saturated urban sewage, the future of China's sewage treatment in the main battlefield in the countryside.For the rural sewage treatment market, urbanization will drive the construction of a number of thousand-ton scale sewage treatment plants.Even considering the factors of rural population reduction caused by the increase of urbanization rate, the construction and operation of rural sewage treatment facilities in China can still reach the level of one trillion.According to the estimation of E20 Research Institute, the market space of rural sewage treatment is estimated to be 120 billion yuan after the "13th Five-Year" p

2021/3/12The construction and operation of rural sewage treatment facilities in China can still reach one trillion levelsThe consensus in the industry is that the market environment has indeed changed profoundly.The industry generally believes that due to the increasingly saturated urban sewage, the future of China's sewage treatment in the main battlefield in the countryside.For the rural sewage treatment market, urbanization will drive the construction of a number of thousand-ton scale sewage treatment plants.Even considering the factors of rural population reduction caused by the increase of urbanization rate, the construction and operation of rural sewage treatment facilities in China can still reach the level of one trillion.According to the estimation of E20 Research Institute, the market space of rural sewage treatment is estimated to be 120 billion yuan after the "13th Five-Year" p

View more 2021/3/5Carbon neutrality leads to heated discussion that a national carbon market will be launchedUnder the goal of achieving carbon peak before 2030 and carbon neutral before 2060, how to promote the construction of the national carbon emission rights trading market (referred to as the "national carbon market") in the opening year of the 14th Five-Year Plan and complete the related targets of carbon emission reduction on schedule has become a hot topic in this year's NPC and CPPCC. The Ministry of Ecology and Environment has announced that the construction of a national carbon market has reached the most critical stage to ensure that online trading will start before the end of June this year.The representative members suggested speeding up the construction of the national carbon market system, optimizing the carbon trading mechanism, and promoting the hierarchical development

2021/3/5Carbon neutrality leads to heated discussion that a national carbon market will be launchedUnder the goal of achieving carbon peak before 2030 and carbon neutral before 2060, how to promote the construction of the national carbon emission rights trading market (referred to as the "national carbon market") in the opening year of the 14th Five-Year Plan and complete the related targets of carbon emission reduction on schedule has become a hot topic in this year's NPC and CPPCC. The Ministry of Ecology and Environment has announced that the construction of a national carbon market has reached the most critical stage to ensure that online trading will start before the end of June this year.The representative members suggested speeding up the construction of the national carbon market system, optimizing the carbon trading mechanism, and promoting the hierarchical development

View more 2021/1/29Operating method of manual valveManual valve is a valve operated by handle and handwheel. It is a common valve used in equipment pipeline.Its handle, hand wheel rotation direction clockwise is closed, counterclockwise is open.However, there are individual valves that open in the opposite way.Therefore, attention should be paid to check the open and close mark before operation.。The handwheel and handle on the valve are designed according to normal manpower. Therefore, in the use of the valve, the operator is not allowed to open or close the valve with the help of a lever and a long wrench.Handwheel, handle diameter (length) 320mm handwheel, allow two people to operate together, or allow one person to use the appropriate lever (generally not more than 0. 5m long) to operate the valve. G

2021/1/29Operating method of manual valveManual valve is a valve operated by handle and handwheel. It is a common valve used in equipment pipeline.Its handle, hand wheel rotation direction clockwise is closed, counterclockwise is open.However, there are individual valves that open in the opposite way.Therefore, attention should be paid to check the open and close mark before operation.。The handwheel and handle on the valve are designed according to normal manpower. Therefore, in the use of the valve, the operator is not allowed to open or close the valve with the help of a lever and a long wrench.Handwheel, handle diameter (length) 320mm handwheel, allow two people to operate together, or allow one person to use the appropriate lever (generally not more than 0. 5m long) to operate the valve. G

View more 2021/1/22Maintenance and operation of new valve before commissioningPre-maintenance of new valves before operation is a progressive construction concept to protect valve seat seals from seat damage during installation, welding and commissioning.The pre-maintenance of the valve before it is put into use can make it better realize the functions of conduction, truncation and diversion. It is not only conducive to early detection of problems, timely troubleshooting, eliminating hidden dangers, but also to extend the operation period of the pipeline, which can better provide a basis for the operation and maintenance of the valve after it is put into operation. The valve leakage mostly occurs in the early use, the main reason is in the pipeline construction operation is not standard caused by the sealing ring and valve ball scratches, these scra

2021/1/22Maintenance and operation of new valve before commissioningPre-maintenance of new valves before operation is a progressive construction concept to protect valve seat seals from seat damage during installation, welding and commissioning.The pre-maintenance of the valve before it is put into use can make it better realize the functions of conduction, truncation and diversion. It is not only conducive to early detection of problems, timely troubleshooting, eliminating hidden dangers, but also to extend the operation period of the pipeline, which can better provide a basis for the operation and maintenance of the valve after it is put into operation. The valve leakage mostly occurs in the early use, the main reason is in the pipeline construction operation is not standard caused by the sealing ring and valve ball scratches, these scra

View more 2021/1/15The valve industry will accelerate industrial transformation and upgradingAs the control part of the fluid conveying system, the valve has the functions of cut-off, regulation, flow diversion, countercurrent prevention, diversion and pressure relief. There are many kinds and various specifications.With the continuous development of valve technology, the application field of valves is also expanding, and the demand for high-end valves is expanding, which is not only a period of innovation and development in the valve industry, but also a period to meet the challenges. China's valve manufacturing industry after years of development, in the valve production and technology research and development, has made great progress, some enterprises and products have made good achievements, but the development and production capacity of high-end valve product

2021/1/15The valve industry will accelerate industrial transformation and upgradingAs the control part of the fluid conveying system, the valve has the functions of cut-off, regulation, flow diversion, countercurrent prevention, diversion and pressure relief. There are many kinds and various specifications.With the continuous development of valve technology, the application field of valves is also expanding, and the demand for high-end valves is expanding, which is not only a period of innovation and development in the valve industry, but also a period to meet the challenges. China's valve manufacturing industry after years of development, in the valve production and technology research and development, has made great progress, some enterprises and products have made good achievements, but the development and production capacity of high-end valve product

View more 2021/1/8Six factors should be considered when selecting sealing surface material of valveThe sealing surface is the key working surface of the valve, the quality of the sealing surface directly affects the service life of the valve, and the material of the sealing surface is an important factor to ensure the quality of the sealing surface.Therefore, the following factors should be considered when selecting the sealing surface material of the valve: 1.Corrosion resistance."Corrosion" refers to the process in which the sealing surface is damaged under the action of the medium.If the surface is damaged in this way, the tightness cannot be guaranteed, and therefore the sealing surface material must be resistant to corrosion.The corrosion resistance of the material mainly depends on its chemical stability. 2.Scratch-resistant."Scratch" refers to the damage caused by

2021/1/8Six factors should be considered when selecting sealing surface material of valveThe sealing surface is the key working surface of the valve, the quality of the sealing surface directly affects the service life of the valve, and the material of the sealing surface is an important factor to ensure the quality of the sealing surface.Therefore, the following factors should be considered when selecting the sealing surface material of the valve: 1.Corrosion resistance."Corrosion" refers to the process in which the sealing surface is damaged under the action of the medium.If the surface is damaged in this way, the tightness cannot be guaranteed, and therefore the sealing surface material must be resistant to corrosion.The corrosion resistance of the material mainly depends on its chemical stability. 2.Scratch-resistant."Scratch" refers to the damage caused by

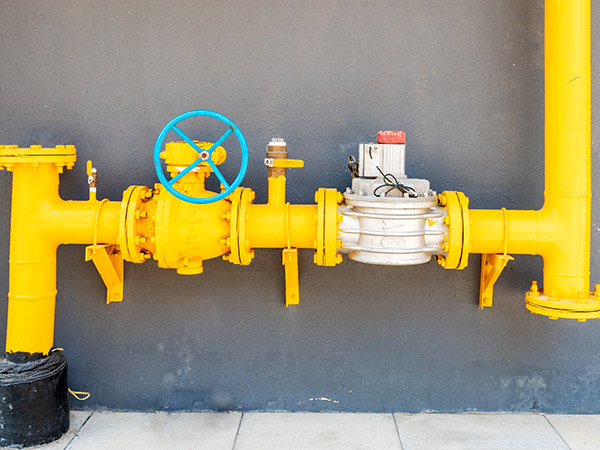

View more 2020/12/25There are five opportunities for natural gas development during the 14th five-year Plan periodIn recent years, with the large-scale development and utilization of natural gas resources in China, the consumption of natural gas has increased greatly in the fields of power generation, civil use, transportation and chemical industry.In addition, countries attach more importance to the green and low-carbon economy, the development of natural gas has jumped to a new level. Natural Gas Industry 'resilient' in 2020 "The term 'resilient' can be used to describe the gas industry in 2020.Even if encounter COVID - 19 outbreak this year, oil prices plunged, clean heating policy shift, and many other "black swans" or adverse effect, in other industries to present type down the precipice, the natural gas market demand still maintain a certain growth rate, shows that the natural g

2020/12/25There are five opportunities for natural gas development during the 14th five-year Plan periodIn recent years, with the large-scale development and utilization of natural gas resources in China, the consumption of natural gas has increased greatly in the fields of power generation, civil use, transportation and chemical industry.In addition, countries attach more importance to the green and low-carbon economy, the development of natural gas has jumped to a new level. Natural Gas Industry 'resilient' in 2020 "The term 'resilient' can be used to describe the gas industry in 2020.Even if encounter COVID - 19 outbreak this year, oil prices plunged, clean heating policy shift, and many other "black swans" or adverse effect, in other industries to present type down the precipice, the natural gas market demand still maintain a certain growth rate, shows that the natural g

View more 2020/12/18Antifreeze and maintenance of valves in winterAfter entering winter, the temperature drops rapidly, the valve often appears the situation of freezing.If left untreated at this point, the pipeline is vulnerable to failure.If it is in some high-risk conditions, accidents may occur.Therefore, the anti-freeze treatment of the valve is very important. Before the temperature drops, it is necessary to carry out a comprehensive insulation work on the valve device to make "winter preparation". Get the tools you need: thermal cotton, wire, pliers, box cutter, and a valid gas alarm in the gas area. Use a box cutter to cut the appropriate insulation cotton to the size of the valve.Use pliers to cut the wire for binding.When wrapping the insulated cotton, tear the insulated cotton slightly so that it goes around the va

2020/12/18Antifreeze and maintenance of valves in winterAfter entering winter, the temperature drops rapidly, the valve often appears the situation of freezing.If left untreated at this point, the pipeline is vulnerable to failure.If it is in some high-risk conditions, accidents may occur.Therefore, the anti-freeze treatment of the valve is very important. Before the temperature drops, it is necessary to carry out a comprehensive insulation work on the valve device to make "winter preparation". Get the tools you need: thermal cotton, wire, pliers, box cutter, and a valid gas alarm in the gas area. Use a box cutter to cut the appropriate insulation cotton to the size of the valve.Use pliers to cut the wire for binding.When wrapping the insulated cotton, tear the insulated cotton slightly so that it goes around the va

View more